Beverage Industry

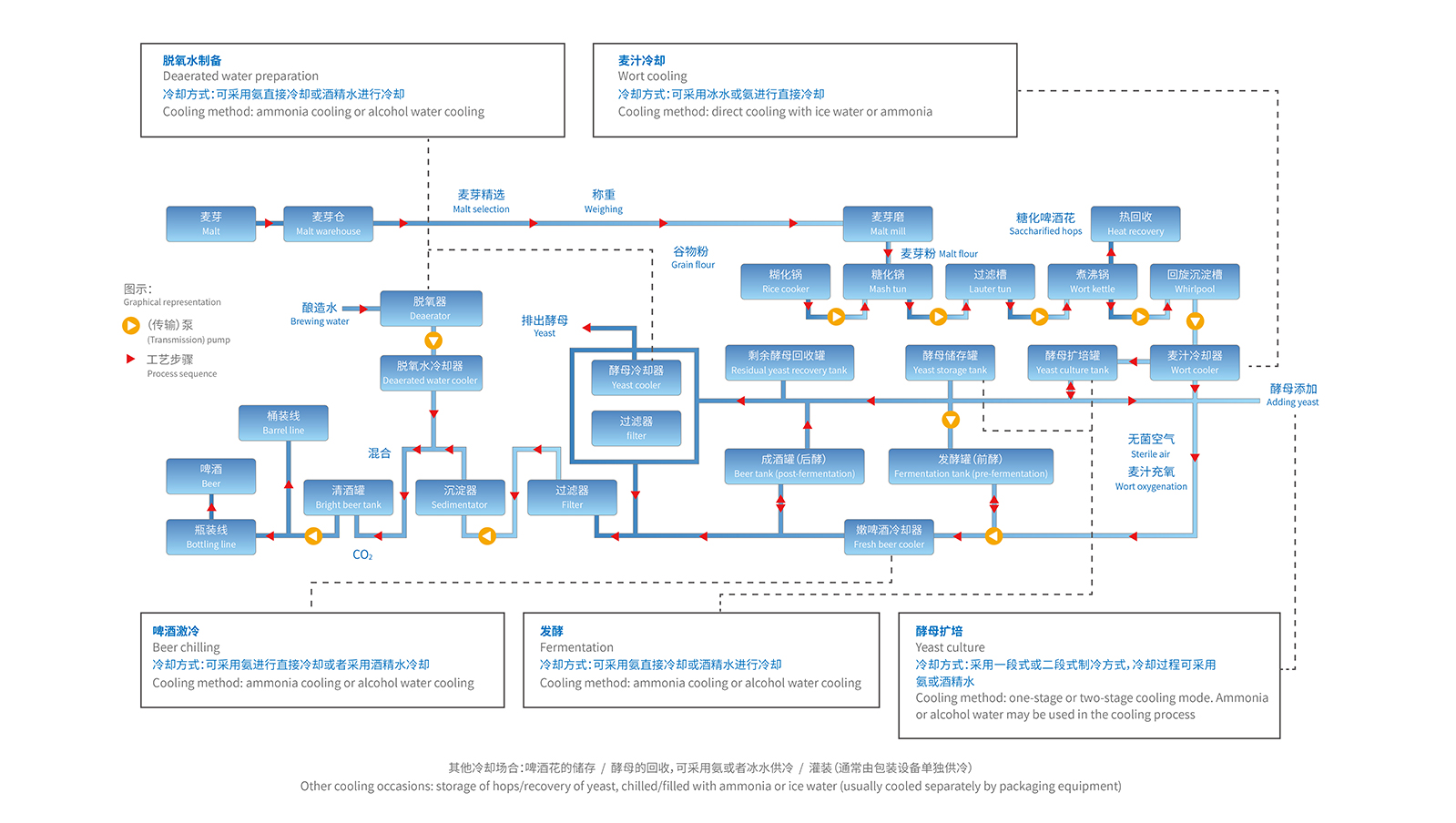

The beer and beverage processing technology requires a lot of cooling and heating processes. In the beer production process, the main way of energy exchange is steam heating wort. After meeting the technical requirements, the wort is cooled to enter the fermentation process for fermentation. The whole process is kept at low temperature. After the fermentation is mature, it enters the filling process. In the whole process of beer, how to combine heating and cooling methods more reasonably is the main problem of energy saving and consumption reduction.