Poultry

At present, the main types of poultry processed and slaughtered are broilers, ducks, and a small amount of special poultry such as goose, turkey, quail, and pigeon. At present, poultry products are mainly quick-frozen cut products, and other products include quick-frozen products, cold fresh pork, cold fresh cut products, cooked food products, etc. The proportion of cold fresh products is gradually increasing.

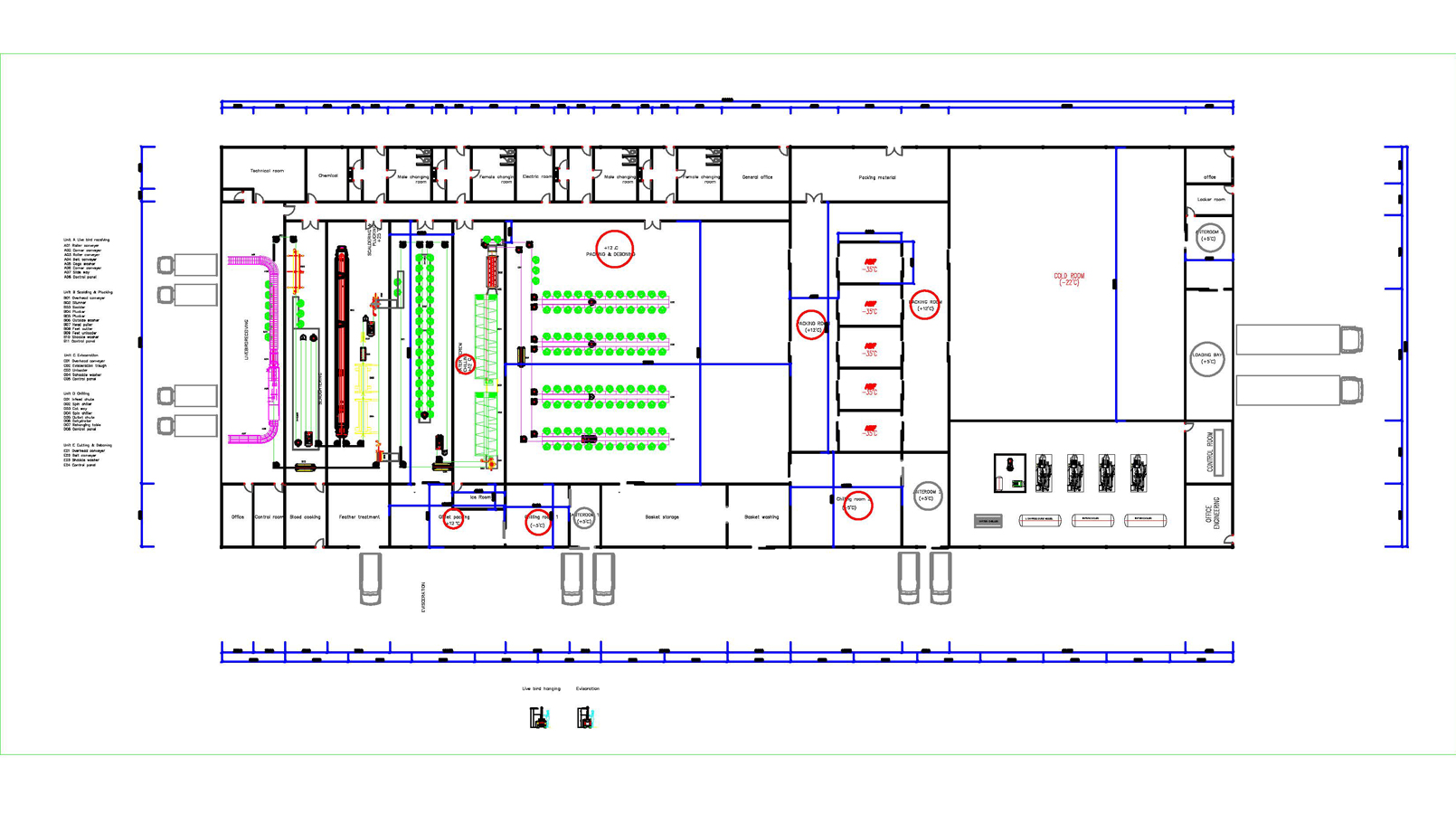

Due to the different needs of the market for chicken products, the meat and poultry processing techniques are also slightly different. International practice is: hanging live chicken → electric stunning → slaughtering → draining blood → scalding → defeathering → flushing → removing head and trachea → cutting claws → changing hang → opening → taking viscera → washing → changing hang → pre-cooling → measurement and classification → packaging. The packaged broiler products are frozen in the freezing room and then sent to storage. The internal organs including heart, liver, gizzards are cleaned, washed and pre-cooled, then bagged, sent into the abdominal cavity of broilers or frozen.

Due to the different needs of the market for chicken products, the meat and poultry processing techniques are also slightly different. International practice is: hanging live chicken → electric stunning → slaughtering → draining blood → scalding → defeathering → flushing → removing head and trachea → cutting claws → changing hang → opening → taking viscera → washing → changing hang → pre-cooling → measurement and classification → packaging. The packaged broiler products are frozen in the freezing room and then sent to storage. The internal organs including heart, liver, gizzards are cleaned, washed and pre-cooled, then bagged, sent into the abdominal cavity of broilers or frozen.